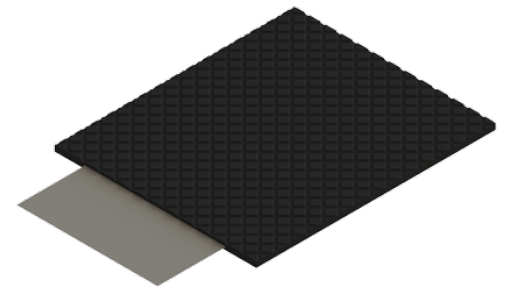

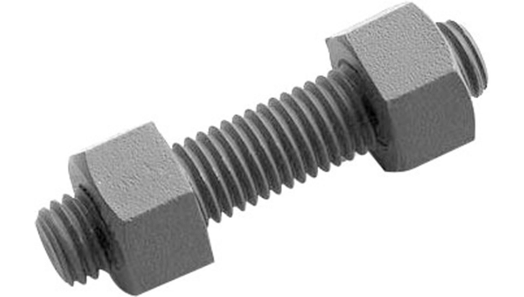

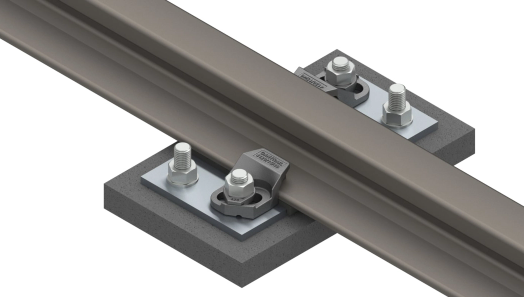

Gallant Technical Solutions Pvt. Ltd. supplies the full range of Gantrail crane rail clips, Gantrail pads, Gantrail accessories, Rail profiles, Grouts, Welding Kit, Anchor Bolts and soleplates. Also we provide services like crane rails Installation, Crane Rail Welding and refurbishment in equipment’s like Rail mounted Gantry Crane (RMGC), Rail Mounted Quay Cranes (RMQC/STS), ship unloaders, wagon tippler, ASRS and Gantry cranes in ports, ship yards and steel plants and other manufacturing industries. We offer the complete crane rail solution from concept and design, to supply and project management, quality assurance and installation, with throughout ongoing support.

00+

Years of Experience

00+

Product Delivered